- Home

- About Us

- Sustainability Management

- Environment

Environment

Overview of Environmental Management

As a company specializing in semiconductor, display, and solar cell manufacturing equipment, Jusung Engineering places environmental preservation and energy efficiency optimization at the core of its management philosophy. The company prioritizes production activities based on stringent self-imposed environmental and energy management standards, exceeding legal regulations. Environmental management is implemented as follows.

- 1. Consider environment and energy as key components of management strategy. Establish goals and detailed plans based on this environmental management policy to promote company-wide environmental management.

- 2. Establish internal environmental management standards based on relevant laws, regulations, and international agreements, including ISO14001. Strictly adhere to these standards to continuously improve environmental management levels.

- 3. Implement greenhouse gas target management to maximize energy efficiency and minimize emissions.

- 4. Encourage all employees to actively participate in environmental management activities, such as energy conservation and resource savings, to continuously improve environmental outcomes and create a pleasant working environment.

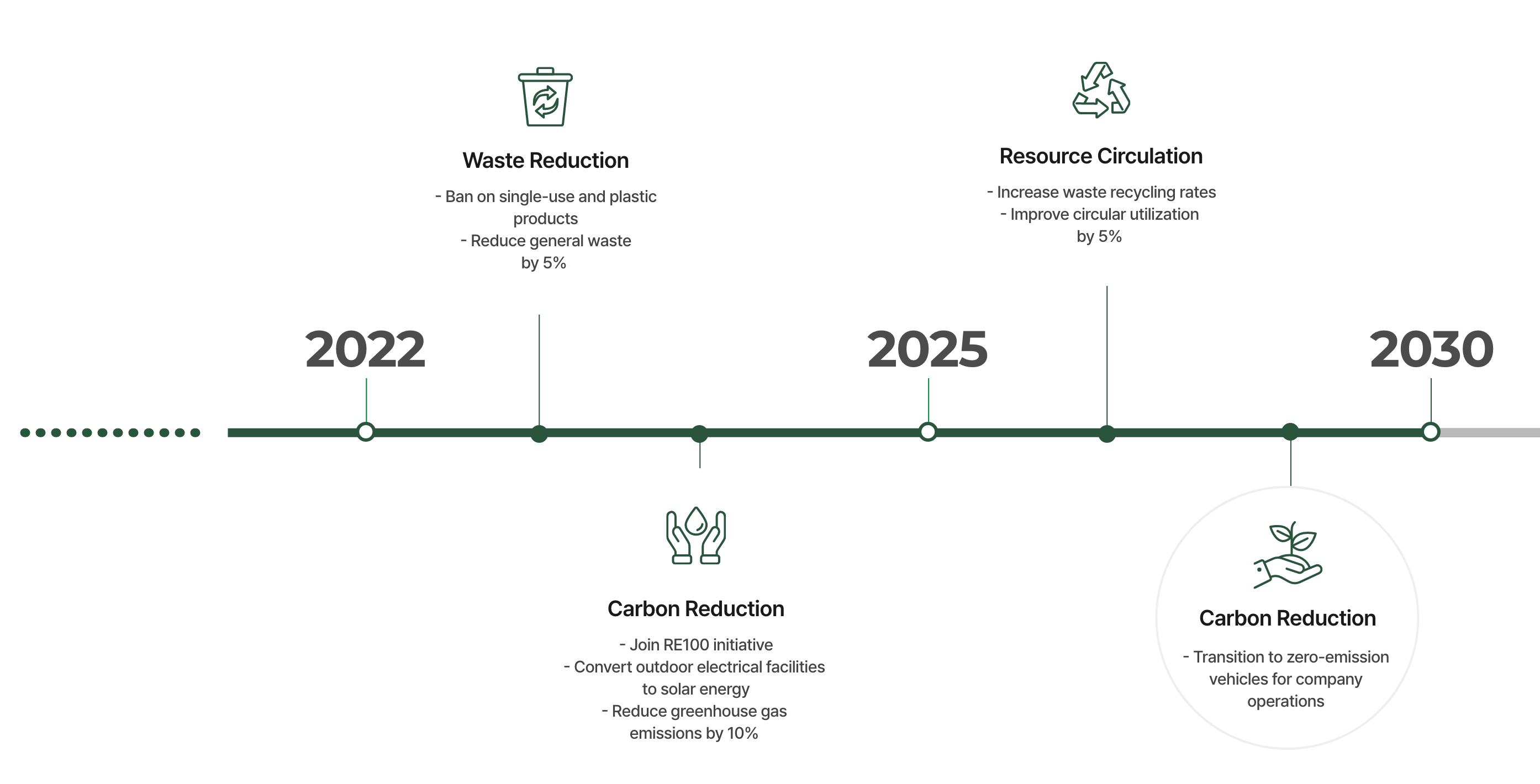

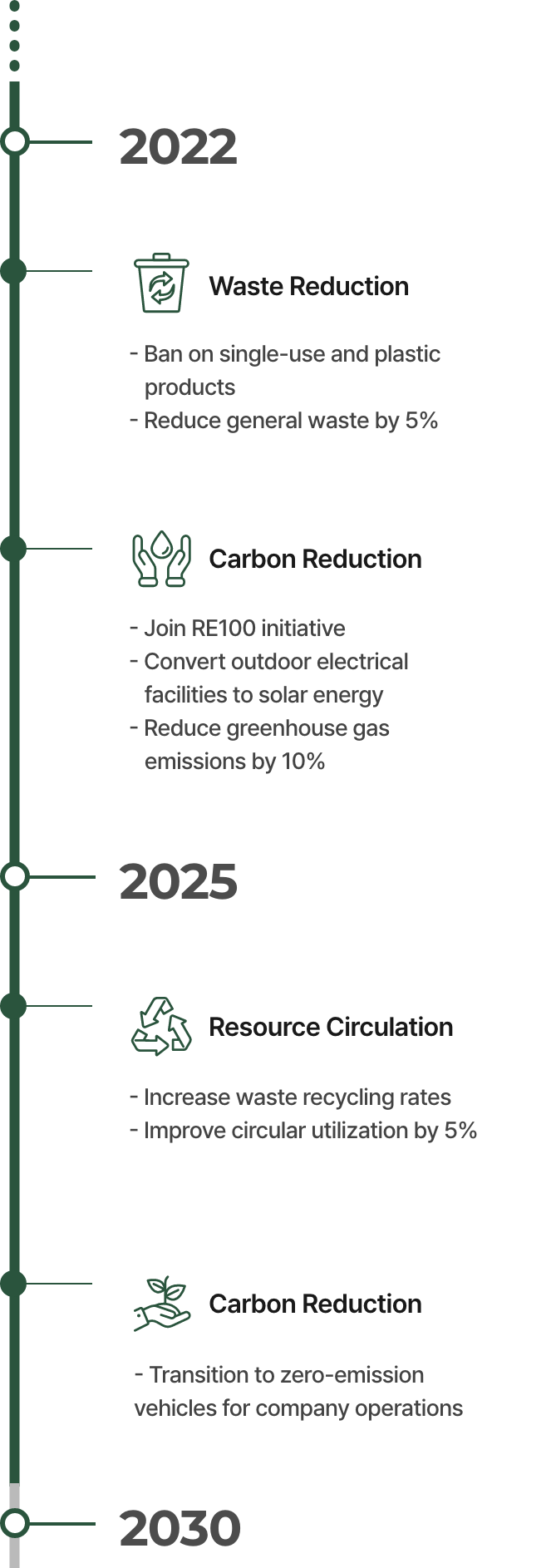

Mid- to Long-Term Goals and Strategies for Environmental Management

Jusung Engineering aims to continuously reduce greenhouse gas emissions and achieve carbon neutrality by

2030 through measures such as optimizing power usage at facilities and improving infrastructure.

Additionally, Jusung plans to decrease waste output and increase recycling rates by adopting recycling

equipment and reducing waste generation by 2030.

Environmental Regulation Compliance Strategy

Environmental Regulation Violations

Jusung Engineering has had no environmental regulation violations in the past three years.

You can scroll left and right.

| Category | Environmental Incident Records | Complaint Occurrence and Response Status | Cases of Environmental Regulation Violations | Emission Surcharge Cases |

|---|---|---|---|---|

| 2023 | - | - | - | - |

| 2022 | - | - | - | - |

| 2021 | - | - | - | - |

Environmental Information Disclosure System

Jusung Engineering registers the previous year’s environmental information in the Environmental Information Disclosure System by the end of June each year. The verified results are transparently disclosed to shareholders and stakeholders in December annually.

-

Information Registration

(June)Environmental Information Disclosure System

(http://www.env-info.kr)

Registration of Previous Year’s Environmental InformationCompanies and Institutions Disclosing Environmental Information

-

Document Review

(Comprehensive)Verification of Information Registration

and Content Review

(Comprehensive Verification Conducted Four Times)Korea Environmental Industry & Technology Institute

-

On-Site Verification

(Sample)Reliability Confirmation Through

On-Site InspectionsKorea Environmental Industry & Technology Institute

-

Information Disclosure

(December)Finalization of Verification Results

and Public DisclosureMinistry of Environment

[ Environmental Information Disclosure Procedure ]

* Jusung Engineering’s Gwangju facility has been excluded from the list of businesses required to disclose environmental information since 2022.

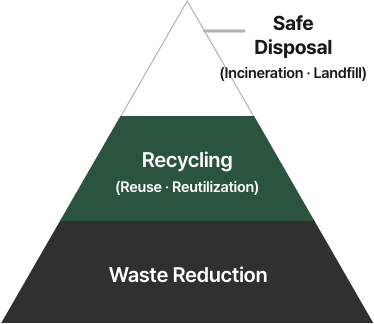

Resource Circulation

Resource Circulation Target Implementation Performance

| Category | Resource Circulation Targets | Resource Circulation Targets Implementation Results |

||

|---|---|---|---|---|

| Final Disposal Rate (%) |

Circular Utilization Rate (%) |

Final Disposal Rate (%) |

Circular Utilization Rate (%) |

|

| 2023 | 79.29 | 1.35 | 9.38 | 62.51 |

| 2022 | 82.06 | 0.26 | 21.61 | 31.64 |

| 2021 | 71.32 | 3.89 | 17.87 | 25.93 |

* Jusung Engineering provides resource circulation information

approved by

national authorities.

Waste Management

Jusung Engineering actively minimizes waste generated during the research and development

stages by adopting recycling equipment and participating in resource recycling through the separation of

general industrial waste.

The company also implements periodic monitoring, analysis, and facility improvements to actively reduce

waste generation.

Waste Emission Targets and Performance

| Category | Target | Actual Emissions | Reduction Rate(%) |

|---|---|---|---|

| 2023 | 200 | 172.25 | 14 |

| 2022 | 200 | 150.83 | 25 |

| 2021 | 200 | 132.33 | 34 |

Waste Emissions and Recycling Amounts (t)

Total Emissions 132.33

Recycled Amount 37.71

Total Emissions 150.83

Recycled Amount 46.96

Total Emissions 172.25

Recycled Amount 108.82

- Designated Waste (Recycled and Refined)

- General Waste (Incinerated)

Waste Resource Circulation System – Resource Circulation Performance Management (TON / Year)

Waste Generation132.33

Waste Generation667.4

Waste Generation172.25

- Final Disposal Amount (Final Disposal Rate)

- Circular Utilization Amount (Circular Disposal Rate)

Water Management

Jusung Engineering minimizes water usage through efficient utilization of water resources, aiming for a 5% annual reduction in water consumption.

Water Usage Targets and Performance

| Category | Target | Usage | Reduction Rate (%) |

|---|---|---|---|

| 2023 | 12,782 | 9,157 | 28 |

| 2022 | 13,455 | 7,772 | 42 |

| 2021 | 14,164 | 10,408 | 26 |

Hazardous Chemical Management

Jusung Engineering conducts environmental impact assessments and chemical risk evaluations on hazardous chemicals used in research and development. This allows for the early identification of environmental and human health risks and ensures stricter management than required by the Chemical Substances Control Act. Material Safety Data Sheets (MSDS) are available at all chemical handling sites for easy access. The company continuously provides specialized training for chemical handlers and conducts joint labor-management inspections to prevent chemical accidents.

Environmental Management Risk Control for Partners

Key Environmental Issue Risk Management

You can scroll left and right.

| Risk Types |

Timeframes | Major Environmental Factors |

Risks and Opportunities | Financial Impact | Response Plans | |

|---|---|---|---|---|---|---|

| Risks | Opportunities | |||||

| Equipment | Short-term | Environmental accidents |

|

|

|

|

| Short-term | Wastewater treatment facilities |

|

|

Fines and penalties for regulatory non-compliance |

|

|

| Short-term | Air emission facilities |

|

|

|

||

| Medium-term | Waste management |

|

|

|

||

| Nature | Long-term | Natural disasters |

|

|

|

|

Raw Material Management

2023 Raw Material Usage

| Primary Materials | Aluminum, SUS | Other Materials | 1 |

|---|---|---|---|

| Primary Material Usage | Aluminum 540.6t / SUS 5.9t | ||

Aluminum Raw Material Usage and Recycled Material (t)

Total Raw Material 522.4(t)

Recycled Material275(t) 37.9(%)

Total Raw Material 204.95(t)

Recycled Material101(t) 20.6(%)

Total Raw Material 540.6(t)

Recycled Material210(t) 38.8(%)

- Aluminum Recycled Material (t)

- Aluminum Raw Material (t)

Climate Change Response

Jusung Engineering recognizes the severity of climate change as a significant risk. As a global equipment manufacturer, the company strives to minimize the impact of climate change across all business activities by setting and managing greenhouse gas reduction targets, establishing organizational systems, and investing in facilities.

Climate Change Scenario Analysis

By analyzing the IPCC Special Report on Global Warming of 1.5°C

and RCP scenarios, Jusung Engineering has set carbon reduction targets.

2050

Net Zero Carbon Emissions

IPCC Special Report on Global Warming of 1.5°C

A report analyzing greenhouse gas emission pathways to limit the increase in the Earth's average temperature to 1.5°C above pre-industrial levels by 2100

RCP Scenarios

Climate change scenarios predicting greenhouse gas concentrations

Corporate Greenhouse Gas Reduction Targets

(Compared to 2019

Levels)

2030

30%

Mid-Term Strategy

-

Actively participate in and respond to government policies related to climate change

-

Reduce process gas usage in manufacturing equipment

-

Apply low-power manufacturing equipment and facility technologies

-

Continuously transition fossil fuel power to renewable energy

2050

60%

Long-Term Strategy

Net Zero Greenhouse Gas

Emissions in Manufacturing

Transition to

renewable energy

-

Apply high-efficiency emission reduction technologies for process gases

-

Adopt low-carbon, eco-friendly alternative energy

-

Accelerate the transition to renewable energy through RE100 membership

-

Continuously develop and apply low-power, eco-friendly products

Climate Change Risk Management Process

-

Identification and Assessment of Risks

Climate change risks are periodically monitored and reviewed from various perspectives, including 'equipment industry and market,' 'regulations,' 'physical environment,' and 'technological trends.' The impacts on business and finance are analyzed in the short, medium, and long term. In particular, the effects on the equipment industry and market are analyzed across three main aspects: 'Equipment and Services,' 'Supply Chain and R&D Investments,' and 'Business Sites.'

-

Decision-Making on Risks and Opportunities

Climate change risks are recognized as critical issues and are used as a standard for decision-making across all management activities.

-

Risk Response and Management

Proactive responses and management strategies are implemented to address internal and external risk factors. Risks related to the changing environment, including uncertainties, loss of opportunities, harm to human life, and business disruptions, are reviewed at the company-wide level. Based on the likelihood and impact of these risks, key risks are identified, and a prevention and management system is established and operated.

You can scroll left and right.

| Risk Types | Periods | Financial Impacts | Response Measures | Opportunity Factors | |

|---|---|---|---|---|---|

| Physical Risks |

Short-Term | Short-Term |

Reduced production capacity at business sites due to natural disasters such as extreme heat, floods, droughts, and typhoons |

Reduce water usage through process improvements in production equipment and machinery |

Cost reduction through the application of energy-efficient products Enhanced customer image through the use of low-carbon energy |

| Long-Term | Long-Term |

/ Damage and depreciation of tangible assets such as buildings, research facilities, and machinery caused by natural disasters |

Improve energy efficiency through advancements in manufacturing facilities and process systems / Invest in gas reduction facilities |

||

| Eco-Friendly Risks |

Policy /Regulation |

Short-Term |

Increased costs associated with greenhouse gas emissions liabilities Rising carbon tax expenses |

/ Invest in gas reduction facilities Transition to green renewable energ |

Additional greenhouse gas reductions through surplus credit sales enabling reinvestment in reduction facilities |

| Technology | Short-Term |

Increased R&D costs for transitioning to low-carbon technologies and facilities |

Develop and apply Low Power Utilize eco-friendly materials and components |

Securing and diversifying alternative resources |

|

| Market | 증기 |

Revenue decline due to reduced demand caused by unmet customer requirements |

Expand the application of eco-friendly products using low-carbon technologies |

Increased access to new markets through the expansion of renewable energy |

|

| Recognition | Long-Term |

Revenue decrease caused by diminished customer recognition and trust |

Increase transparency in reporting internal and external eco-friendly activities and achievements Implement green finance strategies such as issuing green bonds |

Enhanced opportunities for capital funding through attracting investments |

|

Greenhouse Gas Emissions and Energy Usage Management

Jusung Engineering develops long-term strategies and implements phased energy reduction activities in alignment with government greenhouse gas reduction policies, international trends, and domestic/foreign stakeholder demands. Jusung Engineering complies with the 'Energy Use Rationalization Act' and manages greenhouse gas emissions and energy consumption per the requirements for greenhouse gas target management enterprises. Professional institutions conduct energy diagnostics every five years to ensure compliance and optimization.

Greenhouse Gas Emission Targets and Performance Compared to Goals

You can scroll left and right.

| Baseline Year | Greenhouse Gas Emission Target (tCO2) | Greenhouse Gas Emissions (tCO2) |

|---|---|---|

| 2023 | 2,355 | 3,987 |

Greenhouse Gas Emissions and Reduction Rates

You can scroll left and right.

| Baseline Year | Greenhouse Gas Emissions (tCO2) Scope | Greenhouse Gas Emissions (tCO2) Scope2 | Total Greenhouse Gas Emissions (tCO2) | Reduction Rate |

|---|---|---|---|---|

| 2023 | - | 3,987 | 3,987 | 1.2%▲ |

| 2022 | - | 3,937 | 3,937 | 27%▲ |

| 2021 | 9 | 3,086 | 3,095 | - |

Greenhouse Gas Emission Intensity

You can scroll left and right.

| Baseline Year | Total Greenhouse Gas Emissions (tCO2) | Production Volume (units) | Greenhouse Gas Emission Intensity |

|---|---|---|---|

| 2023 | 3,987 | 28 | 142 |

Energy Usage Targets and Performance Compared to Goals

You can scroll left and right.

| Baseline Year | Energy Usage Target (TJ) | Energy Usage (TJ) |

|---|---|---|

| 2023 | 0 | 83 |

Energy Usage and Reduction Rates

You can scroll left and right.

| Baseline Year | Energy Usage (TJ) Scope 1 | Energy Usage (TJ) Scope 2 | Total Energy Usage (TJ) | Reduction Rate |

|---|---|---|---|---|

| 2023 | - | 83 | 83 | 1.2%▲ |

| 2022 | - | 82 | 82 | 26%▲ |

| 2021 | 9 | 64 | 65 | - |

Energy Usage Intensity

You can scroll left and right.

| Baseline Year | Total Energy Usage (TJ) |

Production Volume (units) | Energy Usage Intensity |

|---|---|---|---|

| 2023 | 83 | 28 | 3 |

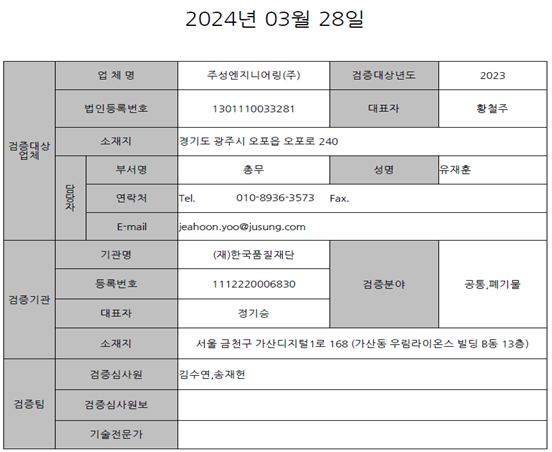

Third-Party Verification of Greenhouse Gas and Energy Usage

You can scroll left and right.

| Verification Body | Auditors | Verification Report |

|---|---|---|

| Korea Quality Foundation | Kim Soo-Yeon, Song Jae-Heon |  |

Third-Party Verification of Greenhouse Gas and Energy Usage

You can scroll left and right.

| Baseline Year | Renewable Energy Usage (kWh)_Self-Generated Consumption |

|---|---|

| 2024 | 39,520.00 |

| 2023 | 155,286.78 |

| 2022 | 81,104.14 |

Carbon Emissions (TON/YEAR)

- Electricity

- Fuel

- Water

You can scroll left and right.

| Years | Electricity(%) | Fuel(%) | Water(%) | Total Emissions |

|---|---|---|---|---|

| 2022 | 3,674(99.9) | - | 4.3(0.1) | 3,678.3 |

| 2021 | 3,987(99.9) | - | 5.4(0.1) | 3,992.4 |

| 2020 | 3,936(99.9) | - | 4.6(0.1) | 3,940.6 |

Environmental Initiative Activities

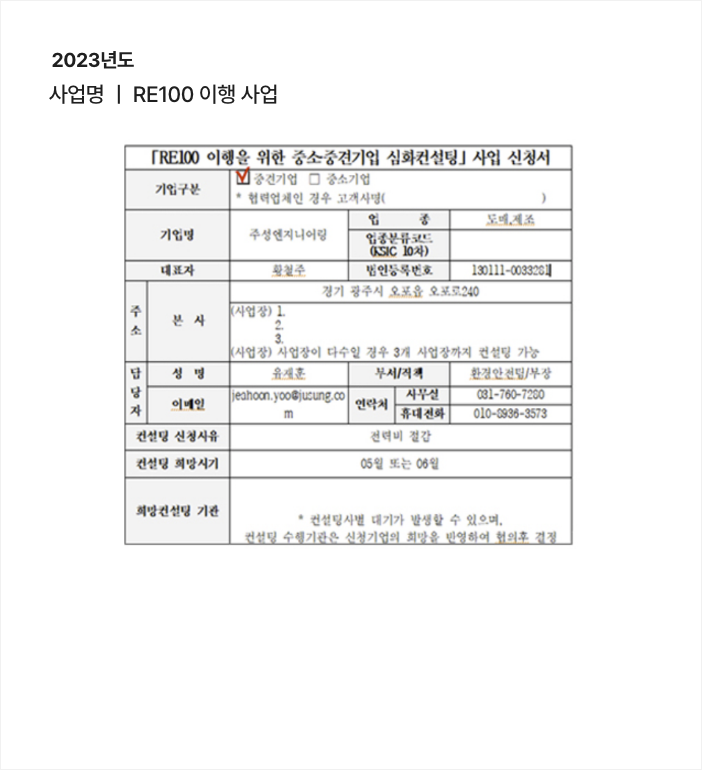

Renewable Energy Projects

In collaboration with the Korea Energy Agency, Jusung Engineering voluntarily implements environmental initiative activities aiming to supply 100% of its electricity usage from renewable energy sources.By using electricity generated from renewable energy, the company expects to achieve its carbon reduction goals and enhance its long-term corporate competitiveness.

Details - Establish company-wide policies to expand the use of renewable energy, set implementation goals, and establish an organizational framework and system to effectively achieve these targets.

Environmental Cleanup Activities

1. Environmental cleanup activities are conducted at least once a month to preserve nature and maintain a clean environment around the Singal-dong area. Employees actively collect litter to create a beautiful and clean community environment.

2. Actively participates in environmental cleanup activities through public-private cooperation with Gwangju City. Linked to Gyeonggi-do's 'Love and War with Trash' project, employees regularly clean a 2km stretch of road around the headquarters and engage in occasional cleanup activities along the Gyeongancheon Stream.